Cold pilger mills for rolling of plates

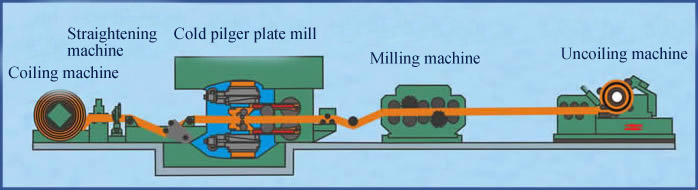

Cold rolling plate mills (HPL) are intended for production of thin-walled sheet by the periodic pilger rolling method.

.jpg)

.jpg)

The mills are effectively combined with continuous casting and milling equipment in one continuous casting-milling module.

Sheet production mini-plant

The plant is intended for sheet production of copper scrap or alloys on copper base.

Production is carried out based on the use of equipment for continuous casting of billet and mill for rolling of the sheet.

Main equipment composition:

- induction furnace;

- blender;

- continuous casting line;

- billet preparation line;

- cold rolling plate mill;

- sheet coiling equipment;

- sheet secondary working line (cold rolling of the sheet with thickness of less than 2 mm., tube welding line and others)

High performance technology developed by “Institute Tsvetmetobrabotka” specialists provides with non-waste production of the sheet and band in the volume of 5000-10000 tpy with minimal capital and current expenses.

Combination of continuous casting with cold rolling provides with the highest quality at the minimum cost.

“Institute Tsvetmetobrabotka” provides with complete delivery of the equipment and technology as well as carries out equipment servicing in the process of assembling and equipment operation.

Cold pilger mills for rolling of sheet and flat profile

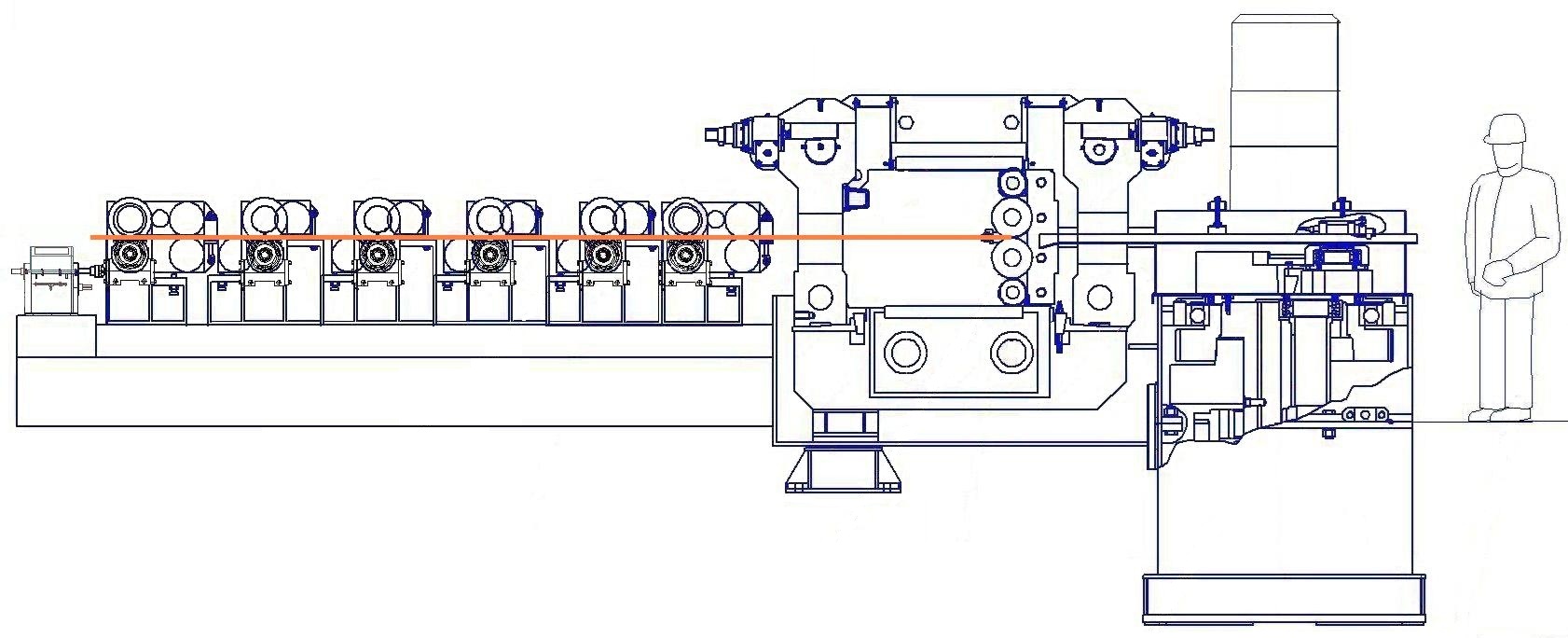

The mills are intended for cold periodical (pilger) rolling of flat and profile sheets (strips).

Rolling is carried out by reciprocally moving rolls with cylindrical or profiled working surfaces. Rolling through two schemes is foreseen:

- rolling by means of two rolls reciprocally moving;

- rolling on the plate by meaпs of one roll reciprocally moving.

Billet feeding and straightening is carried out by means of leveling and feed rollers. Impulsive drive of rollers is carried out by means of planetary-crank transformer. Working stand setting-up is implemented by means of three pressure mechanisms from mill control desk.

Technical parameters of cold pilger mill for rolling of sheet and flat profile

Standard sizes

| Mill size | Billet parameters | Reducing, % | Mill overall dimensions, m | |||||||

| width, mm | thickness, mm | Coil weight, t | Thickness of strip, mm | Maximal billet feeding speed, m/min | For plastic materials | For hard deformed materials | Width | Length | Roll diameter, mm | |

| HPL 250 | 250 | 8-20 | 2.5 | 1-4 | 1.5 | 70-90 | 30-70 | 8 | 25 | 60-130 |

| HPL 400 | 400 | 10-20 | 3 | 1.5-5 | 2 | 8 | 25 | 60-130 | ||

| HPL 650 | 600 | 12-20 | 5 | 2.5-8 | 2 | 10 | 25 | 60-130 | ||

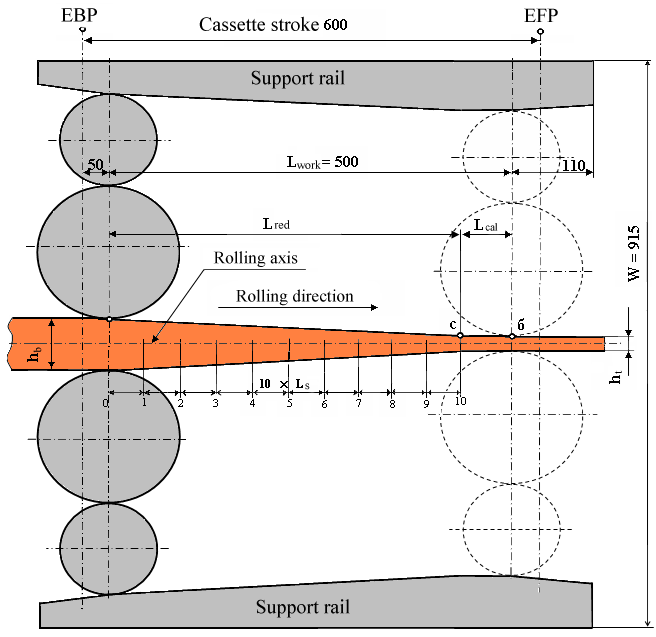

The principal difference of this method from conventional methods of sheet production is that the deformation of initial billet is carried out by means of rollers mounted in the movable cassette which receives a reciprocating movement from the drive of travel. Sheet reducing when cassette moving is performed at the expense of rolls approach leaned on the profiled support rails.

In extreme front and back positions of roll cassette the initial shell advances on the rolling line to feed amount. Since at the return stroke wall reducing does not occur, then half of the total per double stroke (forward and backward) feed value given in back position of the cassette is turned out with the second half given in front position. Reducing of single feed value twice allows to decrease sufficiently dynamic loads in feeding mechanism that provides with more stable and reliable operation of the mechanism.