Tube fixed plug drawing mills

Tube fixed plug drawing mills are intended for production of pipes from high-alloy corrosion-resistant steels and alloys, as well as alloys based on nickel, titanium and zirconium.

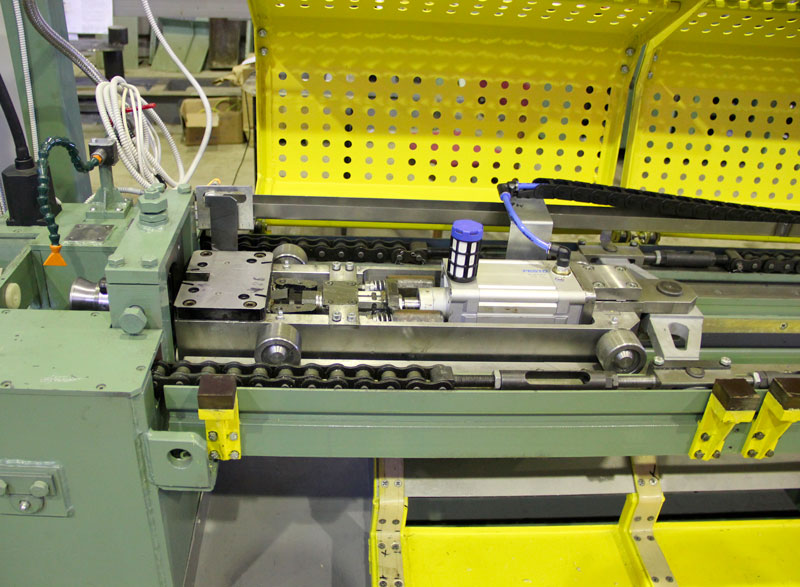

A drawing mill is a complex of mechanical, electrical, pneumatic, and lubrication mechanisms combined into a single machine controlled by a CNC system. The mill consists of the following main mechanisms::

- Loading grate with a receiving chute and storage bin.

- Mechanism for feeding the mandrel rod with the tube inserted into the die. The mechanism is moved to the stop with force. The position of the mandrel rod relative to the feed mechanism is adjustable.

- Single-strand chain stand with an adjustable draw carriage drive and die holder. The die holder design allows for die adjustment relative to the mill axis.

- Electric drive with automatic control and monitoring system. The automatic control and monitoring system provides stepless adjustment of the draw carriage speed from the minimum at the start of drawing to the operating drawing speed determined by the drawing mode. The draw carriage returns to its starting position at high speed, switching to a reduced speed when it stops before the die holder. The draw carriage drive ensures smooth, jerk-free operation without vibration both during drawing and during return. The automatic control and monitoring system ensures drawing and return of the draw carriage in both automatic and manual (setup) modes.

- Pulling carriage grips the forged end of the pipe, pulls the pipe through the die, and automatically releases the drawn pipe into the assembly pocket.

- Die holder installs, secures, and adjusts the die relative to the drawing axis.

- Lubrication system automatically delivers the required amount of liquid lubricant to the pipe's external surface immediately before the pipe enters the die.

- Pocket for receiving finished pipes receives automatically dropped drawn pipes.